Mining companies don’t have to choose between cost savings and sustainability – smart tire management practices can deliver both. Drawing on expertise from Kal Tire and Michelin, this whitepaper provides insights and strategies to help mining operators meet the dual mandate of profit and environmental performance.

Mining companies across the globe are under increasing pressure to meet production targets while simultaneously addressing rising fuel costs, minimizing equipment downtime and meeting increasing regulatory, stakeholder and environmental demands. As the industry advances towards more sustainable and efficient operations, one area that holds untapped potential for improvement is tire management.

In surface mining, tires are one of the highest operating costs after fuel. They can also influence an operation’s carbon footprint through mining vehicle fuel consumption (Scope 1 emissions) and value chain activities (Scope 3 emissions). When tire management is reactive or inconsistent, it can lead to premature wear, elevated fuel usage and unnecessary emissions. However, proactive or predictive tire strategies, developed collaboratively with OEMs, tire manufacturers and service providers, and harnessing the latest technologies, can deliver measurable gains in cost savings, productivity and sustainability.

This whitepaper explores practical, data-driven approaches to tire management that can help mines reduce Scope 1 and 3 emissions and save on operating costs through extended tire life and lower fuel consumption – all without major capital outlays.

Double wins: Reducing costs while cutting carbon

In open-pit mines, loading and haulage operations account for approximately 50-60% of overall operational costs. After fuel, tires are typically the most expensive consumable – the average large metal mine utilizes 900 mining tires each year, which translates into millions of dollars of operational expenditure. Understanding how to preserve and manage the lifespan of tires is therefore crucial to profitability.

Poor tire management practices, like underinflation, improper selection and inadequate maintenance can trigger a ripple of inefficiencies that lead to increased fuel usage and thus, Scope 1 emissions. According to Michelin’s Life Cycle Assessment case study, 70-90% of a mining tire’s environmental impact occurs during its usage, the majority of which is a result of fuel combustion needed to move heavy trucks. This number is high, however, because tire design and condition directly affect performance, this means that operators have control over a major emissions contributor.

The remaining emissions for which mining tires are responsible are classified as Scope 3 – those related to value chain activities, like raw materials production, tire manufacturing, transport and disposal. These emissions are harder to account for, but still significant. Kal Tire’s Maple Program, validated by SCS Global Services, helps mines to quantify their emissions and demonstrate how lifecycle strategies, like tire repair and retreading, can significantly lower the demand for new tires and reduce tire waste at mine sites.

Operation and maintenance can also accelerate wear and damage, which can lead to premature disposal – studies have shown that overinflation accounts for 70.5% of tire damage on trucks and 52.5% of tire damage for front-end loaders, and an estimated 90% of OTR tires never fulfil their intended operating life. The result is that not only are mines buying more tires than they really need and creating more tire waste than is necessary, but they’re also generating avoidable Scope 3 emissions through the production, transport and disposal of new replacement products.

Miles Rigney, Senior Vice President of Kal Tire’s Mining Tire Group, commented:

“Smart tire management offers dual benefits: it lowers operational costs while advancing emissions and sustainability goals. Mines don’t need to choose between the two – they can have both. As stakeholders demand cleaner operations, tire strategies represent a high impact yet underutilized opportunity.”

Inflation matters: the link between tire pressure, fuel use and Scope 1 emissions

The relationship between rolling resistance and the fuel consumption of mining haul trucks has been explored in various studies. Underinflated or degraded tires create more resistance against the road surface, which increases the amount of energy required to make the tires roll. This leads to increased fuel consumption and Scope 1 emissions per haul cycle.

As an example of research that quantifies this correlation in real conditions, a 15-month study conducted at a mine in North America by Michelin and Cascadia Scientific, found that underinflating haul truck tires by 8-10% would increase fuel consumption by 0.26 litres per cycle. Even across a small fleet, that small percentage equates to tens of thousands of litres of additional diesel consumption per year and hundreds of tons of CO2, as demonstrated in figure 1. For a large fleet, these numbers would be even higher.

Today, many mines use tire pressure monitoring systems (TPMS). These technologies continuously monitor conditions within tires, including pressure and temperature, alerting operators to small issues before they generate significant inefficiencies or costly failures. Properly inflated tires also allow trucks to operate closer to their maximum ton-kilometer-per-hour (TKPH) rating, optimizing payloads and reducing cycle times.

Fit for Purpose: Choosing the right tire for the operating environment

Tire selection also matters, and matching the compound to site conditions is essential in maximizing tire life and reducing total cost of ownership.

For instance, for long-distance hauls on smooth roads and in hot conditions, heat-resistant compounds are typically the best option. In contrast, cut-resistant compounds are better suited for shorter hauls and abrasive, rocky environments where tire damage is more likely. Other compounds are tailored for improved traction in wet or soft conditions.

Adam Murphy, Senior Vice President of Michelin’s Mining Tire Business Line, explained: “In extreme environments like mine sites, tire design and quality are critical. By harnessing data on tire performance and site conditions, tire manufacturers can continually optimize key innovations that affect tire life, load-carrying capacity, speed, heat resistance and even energy efficiency. Energy efficient rubber compounds can enable tires to run at a cooler temperature, decreasing their rolling resistance and increasing the truck’s fuel efficiency.”

For example, the Michelin XDR 4 SPEED ENERGY™ tire, which is expected to commercially launch in 2026, delivers 3.6% better fuel efficiency compared to the Michelin XDR 250 C tire, and a savings of approximately 5,300 gallons of fuel or US$24,000 per mining truck annually. For a fleet of 50 trucks, this could equate to almost US$1.2 million in annual savings and a reduction of 2,600 tons of CO2 emissions per year.

Smarter tools, better outcomes: Innovative technology to drive tire performance

Beyond TPMS, emerging technologies in areas such as haul road analysis, fleet diagnostics, and smart loading systems, are making it easier than ever for mines to monitor and manage their tires in real time. The insights these systems generate also elevate tire management practices, allowing them to strategically support companies’ broader corporate objectives.

For example, autonomous tire inspections performed using thermal imaging cameras, AI-powered recognition software and advanced data analysis, can eliminate the need for trucks to leave production, unless there’s an issue that must be addressed, and helps extend tire life through targeted maintenance.

At a Chilean copper mine, Kal Tire’s TireSight autonomous inspections have reduced inspection downtime by 20%. As the mine’s 33 haul trucks pass the TireSight station, thermal imaging cameras now capture three to five full rotations of each front and rear tire, several times a day, without the vehicles needing to stop.

Haul road design and maintenance also have a part to play in preserving tire life and improving the fuel efficiency of haul trucks. Services such as MICHELIN Better Haul Road and software tools backed with GPS and satellite data, such as VBOX, can assess haul road quality and driver behaviors – highlighting areas where tire wear and fuel burn increase due to issues, like poor road conditions or aggressive cornering. This enables site managers to target specific areas for improvements, leading to optimal routes, less tire wear and better fuel usage.

Site severity studies provide additional insights into how road conditions, loading zones and operational practices affect tire life. These studies have helped many mines identify high-impact areas for corrective action. Additionally, volumetric scanning technologies measure material loads in real time, ensuring trucks are evenly and optimally loaded. This reduces unnecessary stress on tires, prevents overloading, and supports consistent performance across haul cycles.

A recent technical analysis by Michelin at a North American iron-ore mine* highlighted the link between data and operational excellence. After the mine switched to a different tire, they saw an 18% decrease in productivity. Michelin’s analysis revealed mismatched tire specs, slower cycle speeds and an increase in tire-related downtime. By recommending a new tire compound better suited to the conditions, alongside a tailored rotation program and better tire pressure management, the mine unlocked US$1.9 million in annual gains and operated more efficiently.

Together, technologies like these lay the foundation for predictive maintenance, autonomous haulage readiness, and low-emission fleet performance – all of which are critical to mine sites of the future.

Partnering with reputable tire manufacturers and service providers that use data-driven insights, proven technical strategies and internal standards around fitter training and operational excellence can deliver measurable improvements in safety and tire performance for mines both large and small. Improved tire life, through proper maintenance and advanced technologies, enables fewer human interactions with the tire, which means fewer opportunities for tire-related incidents.

Murphy added: “Ultimately, small operational changes – selecting the right tire compounds for site conditions, maintaining correct inflation pressure and optimizing haul road designs – can translate into significant environmental and financial gains, while simultaneously elevating the overall safety at the mine site.”

* To receive a copy of this study, contact services.mining@michelin.com

Making tires last: Reducing Scope 3 emissions through repairing and retreading

Every new mining tire has an embedded carbon cost – from materials to manufacturing and shipping. Extending the usable life of each tire reduces the number of new ones that must be produced, minimizing upstream emissions, saving mines money by reducing new purchases and reducing waste at the mine site.

Premium manufacturers like Michelin design their tires to be durable, repairable and retreadable. This enables significant lifecycle extensions without compromising safety or performance and delivers a lower total cost of ownership.

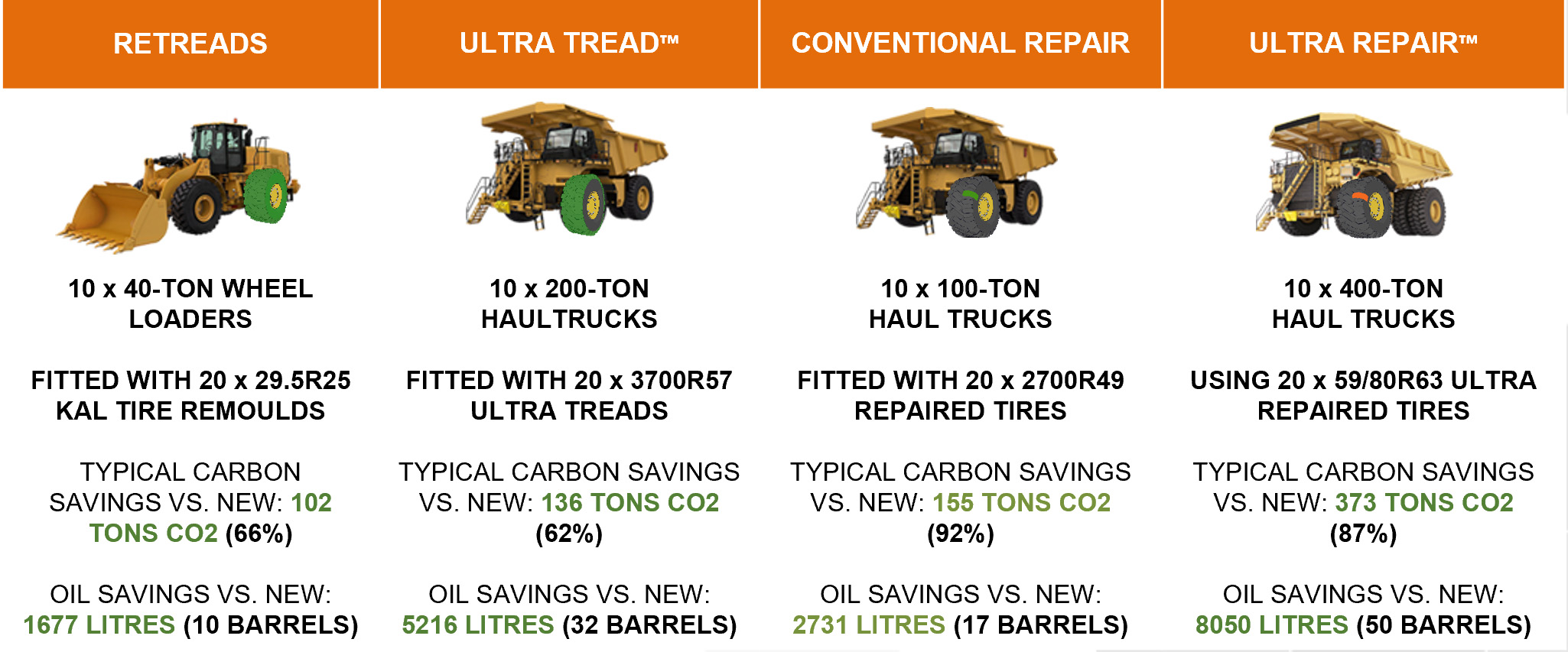

These services are already available at scale in key mining markets, and their environmental and financial benefits are tangible (see figure 2). For instance, Kal Tire has calculated that repairing ten ultra-class haul truck tires using its KalPRO™ Ultra Repair service, rather than buying new, could cut costs by 87%, save 373t of CO2 emissions and eliminate the need for 8,050 L (50 barrels) of oil.

“Mines that implement structured repair and retread programs can reduce their procurement costs, lower shipping expenses and avoid premature disposal of tires that still have viable life remaining,” explained Rigney. “In some cases, mines can even restore tires that have previously been scrapped back into service. Tire life extension is an underutilized, but very impactful lever for sustainability and profitability in mining.”

Strategic tire management - a lever for resilient, responsible mining

In summary, mining operations don’t need to choose between cost savings and emissions reductions. As demonstrated in this paper, strategic, data-supported tire management practices offer a clear pathway to achieve both, and highlighting the mutual benefits can only strengthen the business case for investments in this area, regardless of which is the primary objective.

“From fuel savings and productivity gains to Scope 1 and Scope 3 emission reductions, effective tire strategies deliver real impact,” said Murphy. “The shift towards more sustainable, longer-lasting tire choices, and from reactive to proactive management—using tools like TPMS and haul road diagnostics—can transform mining fleets into more efficient, sustainable business assets. And all of these tools are available to mines right now.”

Furthermore, as regulatory pressures increase and environmental, social and governance (ESG) reporting becomes more rigorous, mining companies that implement smarter tire practices now will be better positioned for long-term success.

“Tires aren’t just consumables—they’re strategic assets,” Rigney concluded. “With the right management, they can be a part of both financial and environmental resilience in mining operations. Smart, strategic collaboration and partnerships with tire manufacturers and service providers are key to unlocking these next-level advantages.”

More information

Contact us for more information about any topics in this whitepaper.

Click here to read more about Michelin’s mine and quarry services.